It can also be further processed using well-known chemical used in a variety of applications, including the production of synthetic rubber. These materials are used in a range of consumer products. The key to realizing these benefits, as with any bio-based product, is a highly productive and efficient microbe able to use renewable sources of carbon and energy (such as corn, sugar cane, or cellulose) in a commercial bioprocess. Today, most organic chemicals are derived products cost competitive with their petroleum. Synthetic biology, dramatically improving an existing process for commercial production of cephalexin, a synthetic antibiotic. Major biotechnology is used in the production with dramatically lower greenhouse gas emissions. The cost and measure of enzymes needed to produce cellulosic biofuels and renewable chemicals and reducing production facility capital and operating costs are much reduced by eliminating the need for enzyme produced in a separate refinery.

The current market for adipic acid is about $ 26 billion. Verdezyne is developing a cost-advantaged, environmentally friendly fermentation process could cut the production costs of adipic acid. The acids produced during the digestion are neutralized by calcium carbonate to form the same salts the ruminant does. Chemical processes are generally energy-intensive, so, as technologies mature and advance, we envision that future processes will include a single-step biological process. The biosynthetic pathways to produce finished fuel products do not exist in the native E. Coli host, and prior to our efforts alkane biosynthetic genes were unknown.

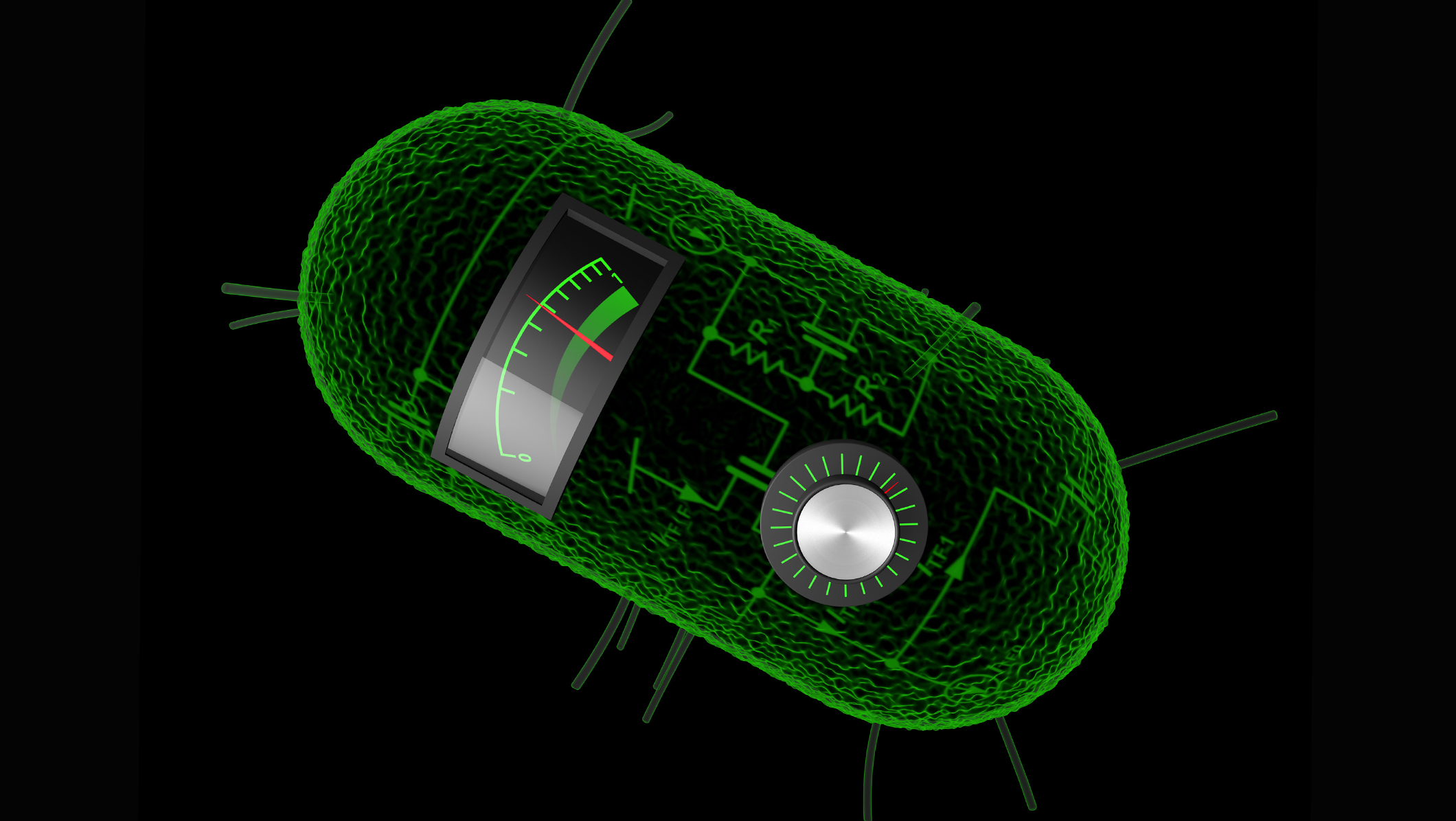

A key application of synthetic biology is the design of new metabolic pathways in microbial expression systems towards innovative products, such as biofuels and new chemical building blocks. However, the long-term market potential is much greater. Organic acid markets are of interest because there is an existing market for large quantities for use in foods, beverages and chemicals. It is possible that renewable materials can entirely replace petroleum derived organic acids if costs could be lowered and integrated large-scale processes developed. Organic acids can be tailored for biofuel production or as biotechnology replacements for petrochemicals and plant oils in a range of products ranging from fuels, chemicals, cosmetics, and food additives. It has targeted demonstration-scale production of succinic acid in 2014, and anticipates first commercial-scale is planned.

As long as refined sugars are the major source of carbon it will be difficult to lower costs. Thus, the technology affects the direct production of renewable chemicals from plant-derived carbohydrates, a more sustainable technologies to replace traditional, fossil fuel-based processes. Algenol process to produce ethanol and high-value organic green-chemicals directly from carbon dioxide, water, sunlight. By locating their primary production facility, a joint venture in Brazil. It develops new production processes based on modern biotechnology. The company is trying to diversify into a variety of markets (such as pharmaceutical precursors, household products, carbon capture and waste water treatment for example) however its primary partnership has long been with Shell Oil (Europe’s largest oil company) with which it had collaborated since 2006 to find critical pathways for developing economically feasible alternative transportation fuels from renewable nonfood biomass resources. The company hopes to commercialize a lower cost-effective large-scale of ethanol production from cellulosic biomass.

As a general rule, micro-organisms possess regulation mechanisms that make sure the sequential use of the carbon sources present in their environment. The high degree of reduction of carbon atoms in glycerol confers the ability to produce fuels and reduced chemicals at higher yields when compared to the use of carbohydrates. Industrial biotechnology is, as far as possible, based on various renewable resources, such as vegetable oils and fatty acids. In current approach, we use the oxygen already inherent in the biomass to produce high value oxygenated commodity chemicals that can be used to make polyurethanes and polyester plastics. Lignin, a heterogeneous mixture made up of aromatic polymers, is a major co-product produced from second generation cellulosic ethanol plants. Saccharomyces produces ethanol as a byproduct when it ferments sugars found in plant materials. Agricultural waste biomass includes municipal solid waste, sewage sludge, manure, and crops.

In comparison to reagents used in pharmaceutical fine chemical syntheses, hazardous chemicals, e. g. Sodium Azide, Halogens, Methyl Sulfide, Phosgene, Phosphorus Chlorides, are more often. Codexis is the leader in modifying enzymes to specific chemical reactions. Total fine chemical industry is subject to a high degree of regulation even more so than the chemical production is involved. In custom manufacturing, a specialty-chemicals company outsources the process development, pilot plant, and, finally, industrial-scale production of an active ingredient, or a predecessor its, to one, or a few, fine chemical companies.

The U. S. Pharmacopeia codified quality standards for Active Pharmaceutical Ingredients. Plastics from renewable raw material imports and are, usually, biodegradable. The new bio-based products can be much increased, allowing customers to choose fully renewable products without sacrificing performance. Complex technical constructions as the composite bow were based on combination of animal and plant-based materials.